After the equipment is electrified and aerated, the bin is placed on the positioning module, and the loading tray flows out from the bin, then the robot sucks the products on the tray to the transit mechanism. The linear module sucks the products from the transit mechanism and places the products to the receiving tray after visual alignment.

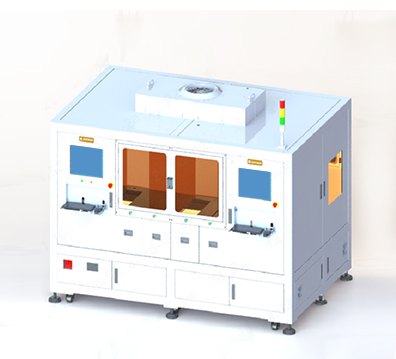

Equipment Weight:750KG

Equipment Dimension:750mm*800mm*2000mm

Rated Voltage:220V

Rated Power:15KVA

Gas Supply Pressure:0.5~0.7Mpa

1.High cleanliness. Applied in class 100 clean rooms;

2.High precision. Use Mitsubishi robots / INOVANCE servo motors, equipment accuracy of ± 0.02mm��;

3.Highly intelligent. Motion control in conjunction with vision systems to effectively eliminate incoming defects and monitor production defects. It can automatically generate data reports;

4.High efficiency. The machine UPH reached 1800 PCS;

5.High yield. 99.99% of equipment output yield;

6.The use of 4-axis manipulators for rapid handling and angle adjustment;

7.Self-developed vision system;

8.Multiple fool-proofing designs for safety and reliablity. Automatically alarm when the abnormalities appear.