After the equipment is electrified and aerated, the whole PCBA board is placed on the locating carrier, and the carrier table automatically enters into the cutting station. The CCD takes a photo of each cutting position and calculates it; the gantry cuts according to the visual real-time position, and the two tools are synchronised. After the cutting is completed, the review camera reinspects each cutting position and uploads the results to the cloud.

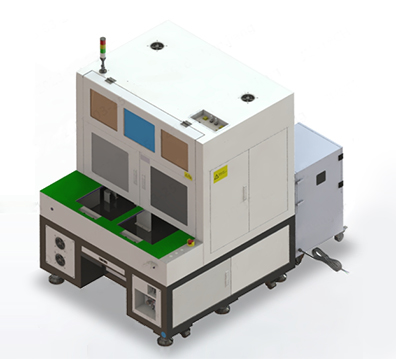

Equipment Weight:900KG

Equipment Dimension:1400mm*2000mm*1800mm

Rated Voltage:220V

Gas Supply Pressure:0.5~0.7Mpa

1.Adopting multi-mill cutting system to shorten time, save labor, meet the needs of mass production, improve production efficiency and ensure quality at the same time;

2.High-speed electric axis drives the milling cutter mounted on it to rotate at high speed, realizing stress-free automatic division of PCBA panels;

3.Tool magazine intelligent system. Intelligent control of broken tool, service life and tool change;

4.CCD alignment testing system, full-time monitoring of cutting quality and tool using throughout the process;

5.Support for product traceability and uploading to MES systems;

6.Broken tool testing and alerting;