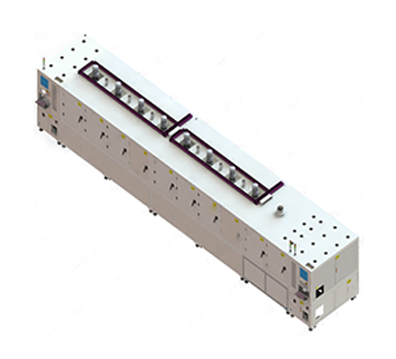

After the equipment is energized and aerated, the equipment loader automatically places the product inside the curing carrier, and the product is scanned with the carrier to upload the information to the cloud.

The system assigns curing channels and the carriers are automatically transported to the corresponding channels.

Equipment downloader receives cloud information to automatically go to the appropriate channel to connect the cured carrier. The product will be removed, and the carrier automatically back to the upper feeder to take on new products.

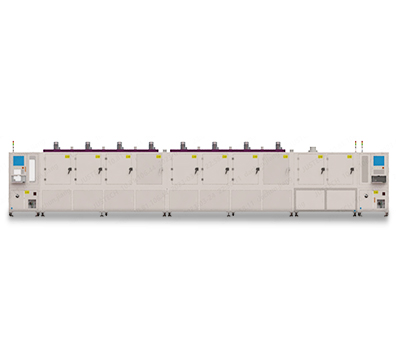

Equipment Dimension:12000mm*2200mm*1800mm

Rated Voltage:380V

Rated Power:75KW

Gas Supply Pressure:0.5~0.7Mpa

1.Adopting precision temperature control system, the equipment can precisely control the temperature, and the fluctuation is ±5℃ around the expected one;

2.Automatic tunnel type furnace has programmable controller, two-dimensional code information tracking system. High precision, easy to operate, and it greatly improves productivity;

3.Smooth and adjustable conveyor belt, maintenance-free design, saving time and effort;

4.When the actual tested temperature exceeds the set value of over-temperature protection thermostat, the heating power will be cut off automatically, which plays a double protection function and is equipped with a safety device, which can operate continuously for a long time, energy saving, environmental protection and strong safety performance;

5.Professional air transport system design ensures the consistency of thermal conduction, convection and temperature uniformity in the furnace;

6.Multi-heating hot air circulation recovery system ensures environmental protection and energy saving���;